|

Background. Recirculating systems offer several advantages including a large effective water volume, ease of cleaning, and require little electrical support due to centralized filtration and heating. This system was constructed for breeding and rearing cichlids (and to fit in a specific area of the basement!). Three 40 gallon breeders are used to house adult fish. Fry and juveniles are housed in the five- 8 gallon and five-18 gallon plastic containers. These containers were purchased at a local discount store for $3.50 and $6.50, respectively.

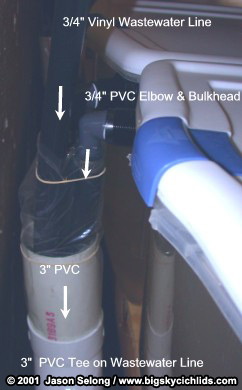

Materials. The stand for this system was constructed of fir 2 x 4 obtained at a local lumber yard. The dimensions of the horizontal boards matched those necessary to accommodate the three 40 gallon breeder aquariums the system was constructed around. Plywood (1/2") was used on the lower two shelves to provide support for the plastic aquariums. The eight vertical supports were dado cut (1/2" deep) to lock into the horizontal supports and secured with carriage bolts. The dado/carriage bolt combination allows easy breakdown of the stand, if necessary. The outlet plumbing to each "tank" was provided by 3/4" bulkhead fittings. A screened insert prevents fish from entering the plumbing system. The water then enters a 3/4" PVC elbow, 3/4" vinyl hose, and empties into the return line. The wastewater line is constructed of 3" thin wall PVC with three 3" PVC tees where the vinyl tubing enters the waste line. Each tee is shrouded with 3" PVC that the vinyl tubing inserts into. This provides an easily accessible waste line, did not require hard plumbing the lines from each tank, and allowed multiple tanks to be plumbed into each of the three tees.

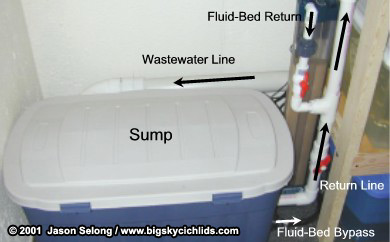

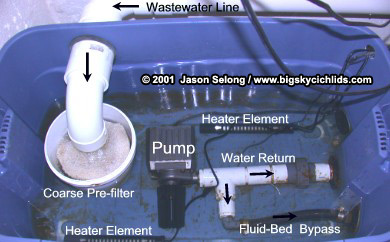

The wastewater line then empties into a 40 gallon sump. A coarse filter pad held in a 12" diameter bucket provides pre-filtration of incoming waste water. Several ball valves were used to bypass water into the fluid bed filter (Lifeguard FB-900). The fluid bed filter provides biological filtration. Water is circulated by an Eheim mag drive 2400 pump and heating is provided by twin AZOO brand 500 watt heaters in the sump. The twin heating elements are operated by a single control unit mounted on the system stand. The water supply lines to each tank were constructed of 1-1/4" thin wall PVC. PVC tees fitted with reducing bushings and 3/4" drum spigots provide relatively inexpensive water flow control.

Based on intial operation, several improvements may be suggested. First, each bulkhead was fitted with a schedule 80 PVC 3/4" elbow that connected the bulkhead to 3/4" vinyl tubing which carried wastewater to the wastewater line (see second photo above). This small elbow greatly constricted the maximum outflow rate. This did not present a problem on the smallest tanks but the larger tanks were subject to flooding at relatively low inflow rates. This required the 3/4" elbow to be removed and replaced with 2" PVC elbows that were fixed to the 3/4" bulkhead outlet and 3/4" vinyl tubing via reducing bushings. This greatly increased the maximum outflow rate. Second, there is no backup in the event of pump failure or tank overflow due to a clogged return screen. Possible remediation for this problem could be either a second pump running in tandem with the first or fitting each tank with air-driven filtration. In this system there is scant sump space which would allow the placement of a second pump and in the event of a tank overflow, the system would shutdown anyways when the sump became dewatered. Some systems, however, may benefit from running two smaller pump in tandem to limit the affect of a pump failure. Sponge filters powered by a large air pump run from a PVC manifold are probably the best backup for a system of this size and type. This alternate system would continue to circulate water in the event of a pump failure or overflow that dewatered the sump and allow survival until the system could be restarted. A large air pump could also be used as a backup or main circulation source for other stand alone aquariums in the fishroom as well. Finally, there is no way to control pathogen cross-contamination on this system. Fish placed on the system must first be quarantined elsewhere. An inline UV sterilizer would be a solution, though not at all cost effective, to limit any pathogen contamination among tanks. Conclusion. The pros of a recirculating system include the ability to segregate adult and especially juvenile fish into small rearing containers but maintain good growth rates due to the large effective water volume. Centralized heat and filtration also reduce electrical costs and maintenance time. The cons include a reduced capacity to limit disease transfer -though a UV sterilizer could be added to the return line, and the noise, as if a small creek is running through the basement! This system has preformed quite well and allows the maintenance of adults and growout of juveniles in a minimum of space. Evaporation has been minimized since all the tanks and the sump remain covered.

|

||

|

Home l Update l Stock List l Gallery | Lake Malawi l Lake Tanganyika l Lake Victoria l Articles l References l Links l About | Contact

© Copyright 1999-2012 All rights reserved.

|

||